In today’s tech-driven world, the need to protect sensitive electronic components has never been greater. Conformal coatings act as a shield, safeguarding devices from environmental stress and extending their lifespan. At the forefront of this essential service is Qual-Pro, a leader in providing top-notch conformal coating services that guarantee reliability and durability.

What is Conformal Coating?

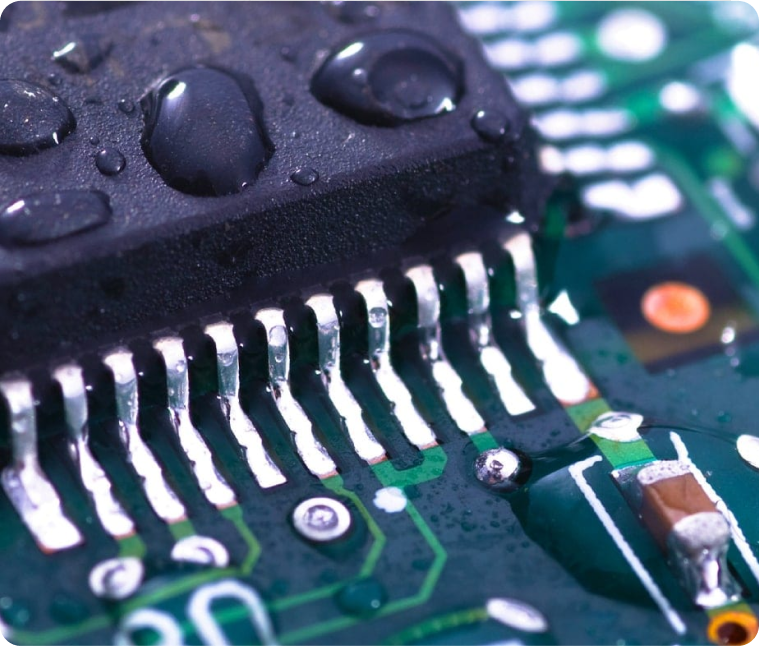

Conformal coating refers to a thin, protective layer applied to electronic circuits to shield them from damage caused by moisture, dust, chemicals, and temperature fluctuations. This non-conductive film conforms to the shape of the components, ensuring complete coverage and protection.

Types of Conformal Coatings

- Acrylic Coatings:

- Offer excellent moisture resistance

- Easy to apply and remove

- Silicone Coatings:

- Ideal for high-temperature environments

- Provide superior flexibility

- Polyurethane Coatings:

- Excellent for chemical resistance

- Common in industrial applications

- Epoxy Coatings:

- Extremely durable and strong

- Often used in high-stress environments

Why Conformal Coatings Are Crucial in Electronics

Conformal coatings are essential for protecting electronics against:

- Moisture and Humidity: Preventing short circuits

- Chemical Exposure: Reducing corrosion risks

- Mechanical Stress: Mitigating wear and tear

These coatings enhance the performance and longevity of devices, making them a critical step in manufacturing.

Qual-Pro’s Approach to Conformal Coating Services

At Qual-Pro, the focus is on precision and innovation. Their state-of-the-art processes are designed to meet stringent industry standards, ensuring unparalleled quality.

Applications of Conformal Coating

- Consumer Electronics: Safeguarding smartphones, tablets, and wearables

- Automotive Industry: Enhancing the durability of electronic control units (ECUs)

- Aerospace and Defense: Providing resilience in extreme environments

The Coating Process at Qual-Pro

- Preparation and Cleaning:

- Ensuring surfaces are free of contaminants

- Application Methods:

- Options include brushing, spraying, dipping, and selective coating

- Quality Assurance:

- Thorough inspections to ensure defect-free application

Comparison of Coating Techniques

- Brushing: Best for small-scale applications

- Spraying: Ideal for even coverage

- Dipping: Ensures thorough coating in bulk manufacturing

- Selective Coating: Precise application for intricate designs

Environmental Considerations

Qual-Pro is committed to sustainability, using eco-friendly materials and processes to minimize environmental impact.

Custom Solutions Offered by Qual-Pro

Qual-Pro excels in creating bespoke coating solutions tailored to unique project requirements, ensuring client satisfaction every step of the way.

Common Challenges in Conformal Coating

Some challenges include coating defects like bubbles or uneven layers. Qual-Pro’s expertise ensures these issues are proactively addressed through advanced techniques.

Advantages of Choosing Qual-Pro

- Decades of experience in the industry

- Advanced tools and techniques

- Commitment to quality and client satisfaction

Client Success Stories

One notable success involved an automotive client who reduced system failures by 40% after implementing Qual-Pro’s conformal coating solutions.

Future Trends in Conformal Coating

The future promises innovations like nano-coatings and integration with IoT, making devices smarter and more durable than ever.

Conclusion

When it comes to conformal coating services, Qual-Pro stands out as a trusted partner. Their dedication to quality, innovation, and customer satisfaction makes them the ideal choice for any project.

FAQs

- What industries benefit from conformal coatings?

- Industries like electronics, automotive, aerospace, and defense benefit significantly.

- How does Qual-Pro ensure quality?

- Through meticulous processes, inspections, and adherence to industry standards.

- What are the main types of conformal coatings?

- Acrylic, silicone, polyurethane, and epoxy coatings.

- Can coatings be customized for specific needs?

- Yes, Qual-Pro offers tailored solutions for unique applications.

- Are conformal coatings environmentally friendly?

- Qual-Pro uses sustainable materials and practices to minimize environmental impact.