Welcome to our comprehensive exploration of Cobalt Production Cost, where we delve into the intricate dynamics of mining and processing this essential metal. Cobalt plays a critical role in various industries, including battery manufacturing, aerospace, and electronics. In this in-depth article, we’ll examine the cost components involved in cobalt production, explore key technologies and processes, and provide insights into the challenges and opportunities facing the cobalt mining industry.

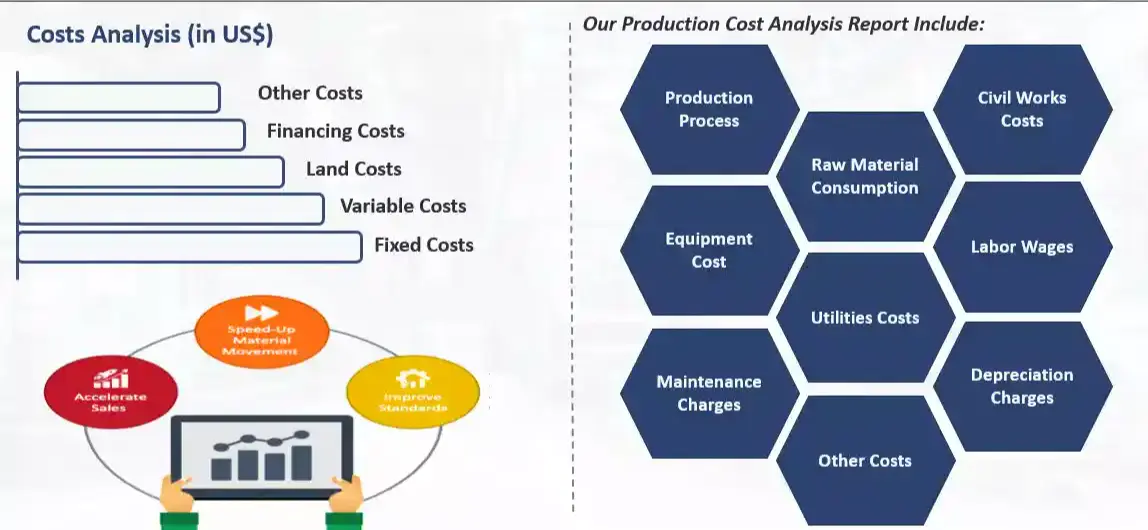

Cost Components of Cobalt Production

1. Exploration and Geological Surveys: Cobalt mining begins with exploration activities to identify potential cobalt deposits and geological surveys to assess their size, grade, and economic viability. The cost of exploration includes geological mapping, drilling, sampling, and laboratory analysis.

2. Mine Development: Mine development costs encompass site preparation, excavation, construction of access roads, infrastructure development, and installation of mine facilities and equipment.

3. Extraction and Processing: The extracted ore undergoes processing to separate cobalt from other minerals and impurities, involving crushing, grinding, flotation, leaching, and solvent extraction processes.

4. Concentration and Refining: After extraction, cobalt-containing ores are concentrated to increase cobalt content and remove unwanted elements. The concentrated cobalt material is then refined to produce high-purity cobalt metal or cobalt compounds suitable for various applications.

5. Energy and Utilities: Cobalt production requires significant energy inputs for mining operations, ore processing, and refining processes. Energy costs include electricity, fuel for machinery and vehicles, and other utilities such as water and heat.

6. Labor and Workforce: Cobalt mining operations require a skilled workforce to operate mining equipment, manage production processes, and ensure safety and compliance. Labor costs include wages, benefits, training, and recruitment expenses.

7. Environmental Compliance: Cobalt mining companies must adhere to environmental regulations governing land use, water management, air emissions, and waste disposal. Compliance costs include permits, environmental monitoring, mitigation measures, and rehabilitation of mining sites.

8. Health and Safety: Ensuring the health and safety of workers is paramount in cobalt mining operations, requiring investments in safety training, personal protective equipment, ventilation systems, and emergency response protocols.

9. Regulatory and Community Relations: Cobalt mining companies must comply with regulatory requirements related to mining rights, permits, royalties, taxes, and community engagement. Building positive relations with local communities is essential for securing social license to operate and mitigating operational risks.

Request For Free Sample: https://procurementresource.com/production-cost-report-store/cobalt/request-sample

Key Technologies and Processes

1. Mining Methods: Cobalt ore is extracted using various mining techniques, including underground mining, surface mining, and solution mining, depending on the geological characteristics of the ore deposit and economic considerations.

2. Hydrometallurgical Processing: Hydrometallurgical processes such as leaching, solvent extraction, and precipitation are commonly used to recover cobalt from ores and concentrates, offering high efficiency and selectivity for cobalt extraction.

3. Pyrometallurgical Refining: Pyrometallurgical processes such as roasting, smelting, and refining are employed to produce cobalt metal from cobalt-containing intermediates or concentrates, utilizing high temperatures and chemical reactions.

5. Recycling and Resource Recovery: Recycling of cobalt-containing materials such as spent batteries, catalysts, and scrap metal offers opportunities to recover cobalt from secondary sources, reducing the reliance on primary mining and promoting circular economy principles.

Challenges and Opportunities

1. Supply Chain Vulnerabilities: The cobalt supply chain is vulnerable to disruptions due to geopolitical risks and labor. Disputes in key producing regions such as the Democratic Republic of Congo (DRC). Which accounts for a significant share of global cobalt production.

2. Ethical and Environmental Concerns: Responsible sourcing initiatives and transparency in supply chains are essential to address these issues.

3. Technological Innovation: Innovation in mining technologies, processing methods, and recycling techniques offers opportunities to improve efficiency. Reduce costs, and minimize environmental impacts in cobalt production. Advancements in battery technologies and electric vehicle (EV) manufacturing drive demand for cobalt. And, stimulate investments in cobalt supply chain infrastructure.

4. Market Volatility: Cobalt prices are susceptible to market volatility, demand fluctuations, macroeconomic factors, and geopolitical tensions. Diversification of cobalt supply sources, strategic stockpiling, and risk management strategies help mitigate price risks.

5. Sustainable Development Goals: Cobalt mining companies are increasingly aligning with the United Nations. Sustainable Development Goals (SDGs) by promoting responsible mining practices, supporting local communities, and contributing to socio-economic development in host countries. Collaboration between industry stakeholders, governments, and civil society is essential to achieve sustainable cobalt supply chains.

Conclusion

In conclusion, cobalt production involves complex cost considerations, technological challenges, and sustainability imperatives that shape the dynamics of the global cobalt mining industry. By understanding the economics of cobalt production, leveraging advanced technologies, and adopting responsible mining practices, stakeholders can address environmental and social concerns, mitigate operational risks, and contribute to a sustainable and resilient cobalt supply chain. As the demand for cobalt continues to grow, driven by the transition to clean energy technologies and the electrification of transportation, the cobalt industry faces both challenges and opportunities in meeting the needs of a rapidly evolving global economy.