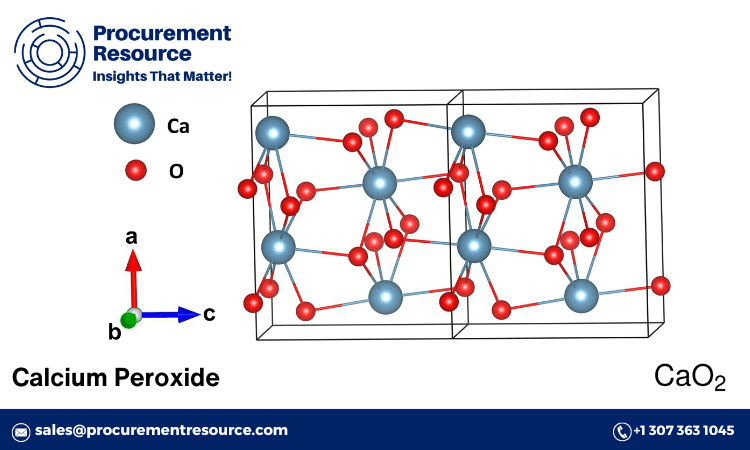

Calcium peroxide (CaO2) is an inorganic compound used extensively in environmental and agricultural applications. Its strong oxidizing properties make it a valuable component in soil remediation, wastewater treatment, and as a seed coating to enhance germination. The production of calcium peroxide involves a series of chemical reactions and processes that ensure the compound is of high purity and suitable for its various applications. This report delves into the manufacturing process of calcium peroxide, the costs associated with raw materials, and the latest developments in the industry.

Manufacturing Report and Process

Production Process Overview

The production of calcium peroxide typically involves the reaction of calcium hydroxide with hydrogen peroxide.

This reaction can be broken down into several key steps:

Request For Sample: https://www.procurementresource.com/production-cost-report-store/calcium-peroxide/request-sample

- Preparation of Reactants: High-purity calcium hydroxide (slaked lime) and hydrogen peroxide are the primary reactants. Ensuring the purity of these substances is crucial for the efficiency and quality of the production process.

- Reaction Phase: The calcium hydroxide is mixed with hydrogen peroxide under controlled conditions. The mixture is typically maintained at a specific temperature and pH to optimize the reaction rate and yield.

- Filtration and Washing: The resultant calcium peroxide precipitate is filtered out from the reaction mixture. It is then washed with deionized water to remove any impurities or unreacted chemicals.

- Drying: The filtered calcium peroxide is dried under controlled conditions to remove any remaining moisture. This step is crucial to ensure the stability and shelf life of the final product.

- Milling and Packaging: The dried calcium peroxide is milled to achieve the desired particle size, enhancing its reactivity and usability in various applications. The final product is then packaged in airtight containers to prevent degradation.

Quality Control

Throughout the production process, rigorous quality control measures are implemented. These include:

- Purity Testing: Ensuring the reactants and final product meet specific purity standards.

- Moisture Content Analysis: Verifying the drying process is complete and the product is stable.

- Particle Size Distribution: Ensuring the milled product meets the required specifications for its intended use.

Raw Material Costs

The cost of raw materials is a significant factor in the overall production expense of calcium peroxide. The primary raw materials include calcium hydroxide and hydrogen peroxide.

Calcium Hydroxide

Calcium hydroxide is derived from limestone through a process of calcination and hydration. The cost of limestone, energy expenses for calcination, and transportation fees all contribute to the final price of calcium hydroxide. Market fluctuations in the availability and cost of limestone can impact production costs.

Hydrogen Peroxide

Hydrogen peroxide is produced through the anthraquinone process, which involves a series of chemical reactions and purification steps. The cost of hydrogen peroxide is influenced by the price of raw materials like anthraquinone and hydrogen, as well as energy costs associated with production. Additionally, transportation and storage costs play a role in the final pricing.

Economic Factors

Several economic factors affect the costs of these raw materials:

- Supply and Demand: Fluctuations in the supply and demand of calcium hydroxide and hydrogen peroxide can lead to price variations.

- Energy Prices: Since both calcium hydroxide and hydrogen peroxide production are energy-intensive processes, changes in energy prices can significantly impact raw material costs.

- Transportation Costs: The distance between raw material sources and production facilities affects transportation expenses.

Overall, the costs of these raw materials directly influence the pricing of calcium peroxide, and manufacturers must continuously monitor market conditions to manage production expenses effectively.

Latest News

Advances in Production Technology

Recent advancements in production technology have focused on improving the efficiency and environmental impact of calcium peroxide manufacturing. Innovations such as:

- Catalyst Development: Researchers are exploring new catalysts that can enhance the reaction rate between calcium hydroxide and hydrogen peroxide, potentially reducing production time and costs.

- Energy Efficiency: New methods to optimize energy consumption during production, such as better temperature and pH control systems, are being developed to lower operational costs and minimize environmental impact.

Market Trends

The demand for calcium peroxide is influenced by various market trends, including:

- Environmental Regulations: Stricter environmental regulations are driving the demand for calcium peroxide in soil and wastewater treatment applications. Companies are increasingly adopting sustainable practices, boosting the use of calcium peroxide.

- Agricultural Sector: The agricultural sector’s growing focus on sustainable farming practices is increasing the use of calcium peroxide as a seed treatment and soil amendment.

Industry Collaborations

Collaborations between industry leaders and research institutions are fostering innovation in calcium peroxide production. Joint ventures and partnerships are focusing on:

- Research and Development: Collaborative research projects are exploring new applications for calcium peroxide, expanding its market potential.

- Sustainability Initiatives: Industry collaborations aim to develop more sustainable production processes, reducing the carbon footprint and enhancing the environmental benefits of calcium peroxide.

Economic Outlook

The global economic outlook also impacts the calcium peroxide market. Factors such as:

- Global Trade Policies: Changes in trade policies and tariffs can affect the availability and pricing of raw materials, influencing production costs.

- Economic Growth: Economic growth in key markets, particularly in emerging economies, can drive the demand for calcium peroxide in various applications.

Regulatory Developments

New regulatory developments are shaping the calcium peroxide industry. For example:

- Environmental Regulations: New regulations aimed at reducing pollution and improving environmental sustainability are increasing the demand for calcium peroxide in environmental remediation projects.

- Safety Standards: Enhanced safety standards for chemical production are prompting manufacturers to adopt more stringent quality control measures, ensuring the safe and effective use of calcium peroxide.

Conclusion

The production of calcium peroxide involves a complex manufacturing process that requires high-purity raw materials, precise reaction control, and rigorous quality assurance. Raw material costs, particularly for calcium hydroxide and hydrogen peroxide, significantly influence production expenses. Recent advancements in production technology and market trends indicate a positive outlook for the calcium peroxide industry, driven by increasing demand in environmental and agricultural applications. Continuous innovation and adherence to regulatory standards are crucial for manufacturers to remain competitive and meet the evolving needs of the market.